The handle is plastic.

Specially designed for right and left handed users.

The handle has a special hand protector for your safety.

The specially applied hard chrome layer provides even higher wear resistance. Specially shaped diamond grains ensure optimum sharpening of the blade.

Around 2 million diamond grains are applied to the surface through special processes.

It is made of steel. It has smooth and sharp edge features.

The handle has an ergonomic design has.

For your safety, it has a large finger guard.

The core of the steel is hard chrome vanadium steel.

It is 25 cm 10" in total, excluding the handle.

How to Use;

- The cutting edge of the knife should be held between 15°-20° and pulled from the bottom to the tip, without pressing.

Note;

- If the thickness of the sharpening edge, that is, the edge of the knife, is too thick, the edge thickness should be thinned to between 0.4 and 0.6 mm.

- If the knife overheats during sharpening, it changes the structure of the steel, reduces the corrosion resistance and hardness of the knife. For this reason, it may also cause your knife to lose its ability to hold an edge.

- The sharpening process should be applied flawlessly from the bottom to the tip, so that a thin wire cap is formed on the edge of the blade.

- To finish the sharpening work, this thin wire/cap formed on the cutting edge should be removed.

- If the burr formed on the edge is not carefully removed, your blade's cutting sharpness and resistance to dulling can be greatly impaired.

- The blade surface should have a straight cutting line, and a jagged or fragmented edge can cause the blade to break.

- Knives should not be exposed to substances that can cause high corrosion, such as salt water, for too long.

→ GRATERS

→ GRATERS

→ STRAINER - COLANDER

→ STRAINER - COLANDER

→ BEATERS

→ BEATERS

→ SHOVELS

→ SHOVELS

→ KITCHEN APPLIANCES

→ KITCHEN APPLIANCES

→ SPATULAS

→ SPATULAS

→ TRANSPORT EQUIPMENT

→ TRANSPORT EQUIPMENT

→ WOODEN PRESENTATION

→ WOODEN PRESENTATION

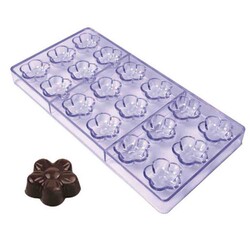

→ PASTRY&SILICONE

→ PASTRY&SILICONE

→ GRINDING MILLS

→ GRINDING MILLS

→ BREAD BASKETS

→ BREAD BASKETS

→ TEA&COFFEE PRODUCTS

→ TEA&COFFEE PRODUCTS

→ DESKTOP EQUIPMENT

→ DESKTOP EQUIPMENT

→ NOODLE&PASTA MACHINE

→ NOODLE&PASTA MACHINE

→ OPEN BUFFET

→ OPEN BUFFET

→ SHARPENER MASAT

→ SHARPENER MASAT

→ KNIFE

→ KNIFE

→ BUTCHER SUPPLIES

→ BUTCHER SUPPLIES